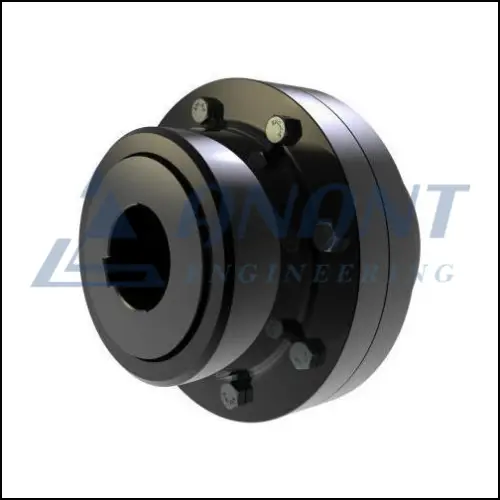

Gear Coupling

Gear coupling

Welcome to Anant Engineering, a renowned manufacturer and exporter of high-quality gear couplings designed to cater to diverse industries worldwide. With our commitment to excellence, we understand the unique requirements of different applications and offer customized couplings tailored to meet clients' specific drawings and specifications. Our flexible gear couplings are engineered to compensate for angular, parallel, and axial misalignments between connected shafts, providing optimal performance and reliability. In this article, we will highlight the exceptional features and applications of our gear couplings, showcasing why Anant Engineering is the preferred choice for industrial sectors globally.

Anant Engineering's gear couplings are meticulously designed to provide unparalleled flexibility and performance in power transmission. Our couplings consist of two hubs with crowned teeth on the outside and two outer sleeves with spur teeth on the inside, ensuring a secure and efficient connection between shafts. This unique design allows our gear couplings to accommodate angular, parallel, and axial misalignments, minimizing stress on connected machinery and reducing wear and tear.

Extensive Applications

Our gear couplings find extensive applications across a broad spectrum of industries. Here are some notable sectors for Anant Engineering's gear couplings:

- Metal Rolling Mills: Gear couplings play a crucial role in metal rolling mills, connecting various machinery components involved in the rolling and shaping of metals. The ability of our couplings to handle high torques, angular misalignment, and heavy loads ensures smooth and efficient operations in this demanding environment.

- Paper Machinery: Anant Engineering's gear couplings are widely used in the paper industry, connecting critical components such as calendars, dryers, and rolls. With their ability to compensate for misalignments, our couplings ensure precise power transmission, enabling optimal paper production.

- Cranes and Dredgers: Cranes and dredgers rely on gear couplings for their lifting and material handling capabilities. Anant Engineering's gear couplings provide reliable torque transmission and accommodate misalignments, ensuring safe and efficient operation of these heavy-duty machines.

- Rubber and Plastic Industries: Gear couplings are essential in the rubber and plastic industries, where they connect various machinery involved in molding, extrusion, and processing. Our couplings enable precise power transmission, contributing to the production of high-quality rubber and plastic products.

- Cement Plants: In the cement industry, gear couplings are used in applications such as kilns, crushers, and conveyors. Anant Engineering's gear couplings ensure reliable torque transmission, withstand harsh operating conditions, and contribute to the efficient production of cement.

- Conveyors and Elevators: Gear couplings are crucial components in conveyors and elevators, facilitating the movement of materials in industries such as mining, construction, and logistics. With their ability to handle misalignments and transmit high torques, our couplings ensure smooth and reliable operation of these material handling systems.

- Compressors, Fans, and Blowers: Anant Engineering's gear couplings are utilized in compressors, fans, and blowers across various industries. These couplings provide efficient power transmission, compensate for misalignments, and contribute to the reliable performance of this equipment.

Specification

| Material | EN9 Forged |

|---|---|

| Type | Full Gear 101 To 119 & Half Gear 101 To 110 |

| Application | Transmitting Torque & Power |

| Surface Treatment | Phosphating, Blackodising |

| HSN Code | 84836010 |

| Packaging | Wooden Box |

| Certification | Material And Hardness Test Certificate On Request |

| Stock | Full Gear 101 To 113 & Half Gear 101 To 110 |